Gearbox Selection

GYSIN GEARBOXES

In medical engineering, in robots, in aeronautics and in motors or apparatus, GYSIN precision gearboxes actuate all kinds of technologies.

Our long experience in the production of gears and gearboxes enables us to offer and manufacture just the right gearbox for your particular application.

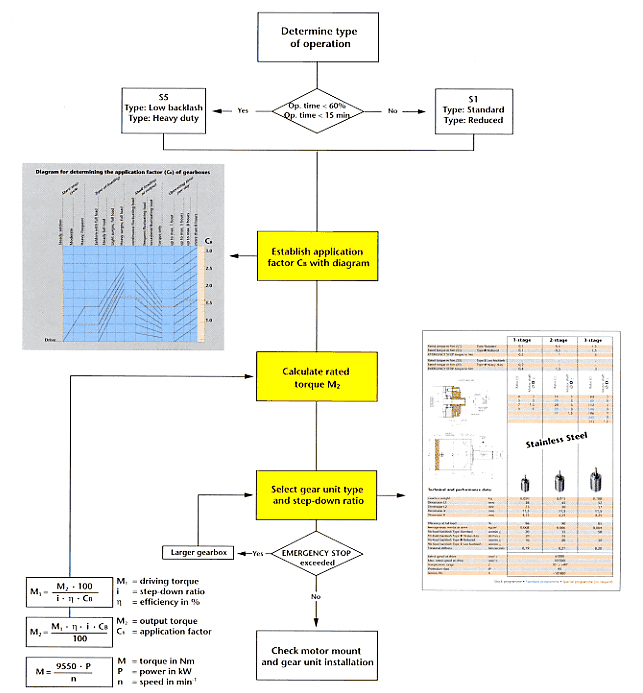

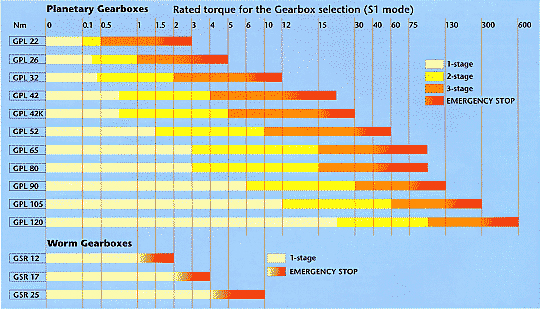

GEARBOX SELECTION

SERVICE LIFE

Because the service life of a gearbox depends on so many different variables, it cannot be predicted with any accuracy. The life can easily reach 20,000 hours of operation or more, but under extremely harsh duty conditions may not even reach 500 hours. The main factors affecting service life are:

- Input Speed

- Output Torque

- Operation Mode

- Ambient Conditions

- Installation In Drive Train

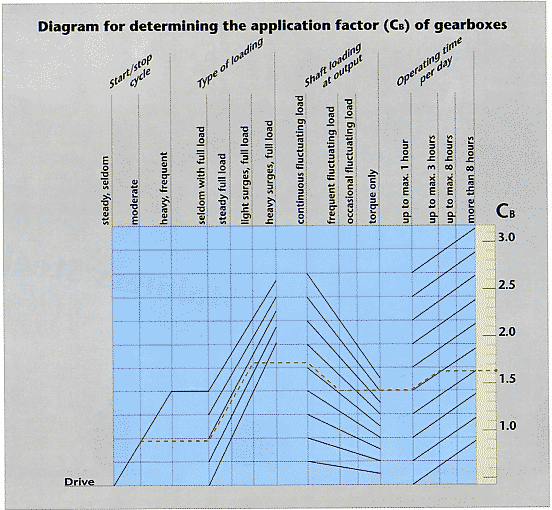

APPLICATION FACTOR CB

Definition of the gearbox’s output torque is the most important consideration when it comes to selecting a GYSIN precision gearbox. In order to take the various duty conditions into account without going into excessive detail, one need only consider the application factor CB, which incorporates the start/stop cycles, type of loading, output shaft loading, and duty cycle.

LUBRICATION

The purpose of lubrication is to prevent direct contact between the moving parts. The use of sophisticated lubricants, therefore, enhances gearbox performance and prolongs bearing life. Effective lubrication ensures:

- Reduction Of Friction

- Reduction Of Wear

- Improved Cooling

- Protection Against Corrosion

GREASE LUBRICATION

The main factors to consider when selecting a lubricant are the ambient conditions, the operating temperature and the input speed. All GYSIN precision gearboxes are lubricated with greases of the very highest quality that take these factors into account. Besides being compatible with the most common applications, these greases provide unmatched, permanent lubrication. As a bonus, they prevent penetration of moisture and foreign objects. GYSIN precision gearboxes are delivered with the cavities filled about 30% with grease. This filling level serves to keep the friction moment and temperature low at normal speeds. The lubrication is suitable for duty in ambient temperatures between -30° C and + 90° C. We recommend servicing, even where synthetic lubricants are used, every 10,000 hours of operation or at least every three years.

MODES OF OPERATION

On planetary gearboxes, it is possible to use the sun gear, the output shaft or the gearbox housing for power input, output or blocking purposes. Consequently, the admissible speed, the torque and the acceleration torques differ depending on the operating mode. In certain case, torque peaks can combine with high cycling rates to produce undesired vibration in the gearbox.

S1 MODE

One speaks of continuous or S1 operation where the gearbox’s operating time exceeds 15 minutes without a break or where the duty cycle is greater than 60 %. In no case may the gearbox housing temperature exceed 70° C.

S5 MODE

Cyclical or S5 operation is selected where the gearbox’s duty cycle is less than 60%. The number of operations per hour can range anywhere from a few to several thousand. If the frequency of start-stop operations exceeds 1000 per hour, the maximum torque occurring must be multiplied by a shock factor to take the additional dynamic loading into account.

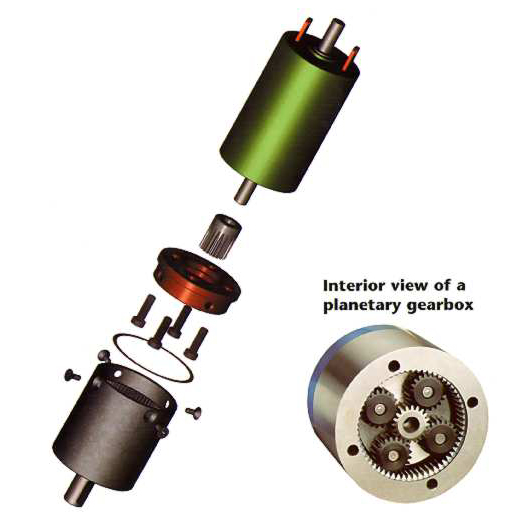

VERSATILE MOTOR MOUNTING

By using straightforward modular mounting parts, such as mounting plate and motor pinion, GYSIN precision gearboxes are attachable to any normal commercial motor. Trained personnel can mount the gearbox on the motor with a few simple steps taking only about 5 minutes.

MOTOR MOUNTING IN 3 EASY STEPS

- Fasten Motor Pinionn

- Screw Mounting Plate In Place

- Put On Gear Unit And Screw It Together

Mounting instructions are provided with every gearbox. The concentricity and run-out tolerances of the motors are defined by DIN 42955-R.

GEARBOX ASSEMBLY

GYSIN precision gearboxes leave our factory individually tested, filled with the right amount of lubricant, and prepared for mounting on the motor specified in the order. They can be put into operation immediately after being mounted.

The standard mounting position is horizontal. In the case of vertical mounting, steps may have to be taken to make sure the upper parts of the gearbox receive proper lubrication. In this case, please enquire. The centring and attachment surfaces must be free of grease, undamaged, and positioned precisely in relation to the shafts of the overall system. Any offset between housing and shaft would apply excessive loading at gears and bearings. Shocks or blows should be avoided when mounting couplings etc., on the gearbox shaft, because they could result in bearing damage.

Search Our Site

Order Information

For online orders, please complete our

online formor contact

sales@maxmar.comfor help with your order.

Need a Catalog?

Contact our

sales departmentfor our full color catalog and assistance with your order!

Maxmar.com

Products for industrial automation.

Copyright 2016 / Maxmar

Terms & Conditions of SalesQuality ManualISO 9001 CertificationContact Info

Maxmar Motion Technologies 9034 Marshall Court Westminster, Colorado 80031, USA

Sales@maximar.comPhone: +1-720-626-2229

Toll Free: 1-888-6MAXMAR

Maxmar Copyright All Rights Reserved © 2023